The Science of Cooling

By David Ren 任大偉

The Need for Cooling

Low temperature food preservation has been a longstanding issue in human history and artificial refrigeration has only been around for a little more than two centuries. Food stored at room temperature rapidly becomes unfit for human consumption, and thus propelled the search for more superior food preservation techniques. Artificial refrigeration began as ice harvesting in the 19th century, requiring manual carving of ice from rivers or lakes, and the subsequent transportation from cold climates to hot climates. Icehouses for food preservation also became popular around this time. Eventually, a much more elegant solution in the form of what we know today as mechanical refrigeration, supplanted manual ice carving.

Frigid Fridge Cooling

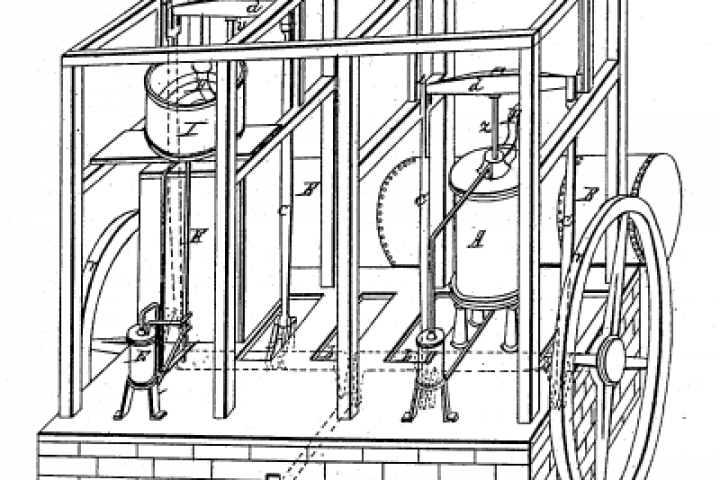

Most refrigerators operate on a vapour-compression cycle that consists of a compressor, condenser, thermal-expansion valve, and an evaporator. The first such closed system fridge was invented in 1834 by Jacob Perkins. Utilising the pressure-temperature relationship of gases, thermal energy (or heat) can be removed from the inside of the fridge to the environment. Ideal gases obey the equation PV = nRT, where the pressure and volume are directly proportional to the temperature of the gas. Hence, decreasing pressure leads to a decrease in temperature.

The expulsion of high-pressure coolant through the thermal-expansion valve leads to a rapid but controllable decrease of coolant temperature. This is called ‘adiabatic flash evaporation’, where no heat or work is done.

In the evaporator, the coolant evaporates (vapourises below the boiling point at that pressure). This process requires the input of energy from its surroundings – in this case the interior of the fridge. Evaporation removes heat, akin to sweat evaporating on skin to cool down the human body. To maximise the efficiency, the coolant vapour must absorb as much energy as possible without boiling, which could damage the machinery. This state is called saturated vapour.

Prior to ejection through the metal pipes in the exterior of the fridge, the coolant gas is compressed, which increases the pressure and temperature. The snaking sequence of metal pipes behind the refrigerator is the condenser, where the excess heat is ejected. This high-pressure, high-temperature liquid is now ready to pass through the thermal-expansion valve to begin the cycle again.

How We Liquefy Air

It is important to note that during the gas expansion process, the valve must be kept insulated from the environment to ensure adiabatic expansion. This subsequent cooling is known as the Joule-Thomson effect and only applies to real gases.

The process of air liquefaction is similar to that of household refrigeration. Originally conceived to produce liquid carbon dioxide for characteristic “heads” on beer, the process of air liquefaction finally became viable on the industrial scale. As a result, liquid nitrogen and oxygen can be produced in a process known as the Hampson-Linde cycle. This process differs from household refrigeration in one crucial step: the gas cooled to its lowest temperature becomes the coolant of the condenser (the metal pipes at the back of the fridge), to allow new air to cool to lower temperatures in a reciprocating fashion.

The impact brought about by refrigeration has been ubiquitous. On-demand cooling has revolutionised the storage of food by prolonging the edible lifetime. As a result, food can also be delivered to far-flung destinations.